Call Us

+86-13503272331

Call Us

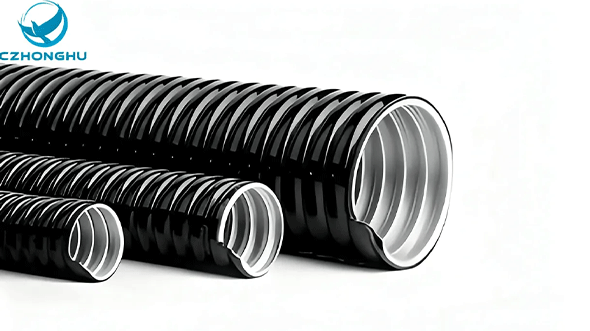

+86-13503272331In industrial automation, machine tool equipment, outdoor lighting, and any application demanding frequent cable movement or complex, non-linear routing, traditional rigid conduits simply fall short. This is where the PVC Coated Flexible Conduit steps in as the ideal solution for safeguarding electrical cables, thanks to its unique dual-layer structure: a resilient internal metal core and a durable external PVC coating.

The core competency of the PVC Coated Flexible Conduit lies in its ability to masterfully resolve the conflict between robust protection and operational ease:

Exceptional Physical Protection: The internal structure, typically made of galvanized steel or stainless steel flexible conduit, offers powerful tensile strength, impact resistance, and crush resistance, effectively guarding cables against severe mechanical damage.

Outstanding Water and Moisture Resistance: The thick outer PVC (Polyvinyl Chloride) coating creates a hermetic, watertight barrier. This allows the conduit system to achieve high IP ratings for water and dust ingress protection, making it specifically suited for humid, multi-wet environments, both indoors and outdoors.

Chemical and Weather Durability: The inherent properties of the PVC material provide resistance to oil, weak acids, and alkalis, significantly extending the conduit's service life when exposed to chemicals or severe weather conditions.

Superior Flexibility: The conduit can be easily bent and twisted, adapting effortlessly to irregular or dynamic wiring paths. This dramatically simplifies complex and challenging on-site installations.

PVC Coated Flexible Conduit is the primary choice for ensuring the reliable operation of critical equipment and systems, predominantly utilized in:

Machine Tools and Industrial Automation: Essential for connecting moving components and protecting control cables that undergo high-frequency flexing cycles.

Outdoor and Port Equipment: Offers high-grade waterproofing and corrosion resistance required to withstand exposure to rain, moisture, and salt spray erosion.

Power Transmission and Substation Equipment: Ensures reliable cable connections, particularly in environments prone to significant mechanical vibration.

Rail Transit and Shipbuilding: Fulfills the stringent wiring system requirements for fire resistance, durability, and operational safety.

When choosing a PVC coated metal flexible conduit, please pay attention to the following points:

Core Material: Verify if the inner core is galvanized steel or stainless steel to ensure it matches the necessary corrosion resistance rating for your specific application environment.

PVC Coating Thickness: A thicker coating generally indicates better abrasion resistance, tear resistance, and enhanced waterproof sealing performance.

Matching Fittings: Specialized flexible conduit fittings (such as dedicated metal or nylon connectors) must be utilized to maintain the overall IP protection rating and grounding integrity of the complete wiring system.

Investing in high-quality, industry-compliant PVC Coated Flexible Conduit is an investment in your project's long-term reliability and maximum installation efficiency. It is more than just a cable protector; it is the perfect solution for complex wiring challenges.